Reducing drastically the ecological footprint of fabrication with fiber laser welding.

Committed to reduced energy consumption.

Carbon Footprint drastic reduction

Industrial fabrication, and the welding process in particular, is a highly energy intensive process involving the consumption of large quantities of gas, electricity and consumables.

Laser welding consumes as little as 1/20th of the energy and gas consumed by TIG/GTAW for the same weld, dramatically reducing the carbon footprint of our customers.

We’re committed to the development of technologies like our Wobble Welder which reduce energy consumption, improve the sustainability of our industry and improve occupational health and safety.

Energy efficiency

When examining energy efficiency, the entire manufacturing process must be taken into consideration. Because of its inherent characteristics, laser welding offers many ways of increasing energy efficiency and reducing manufacturing costs in upstream and downstream manufacturing processes. These factors should be considered when selecting the optimum welding technique. Based on several factors, the laser Welding process is considered one of the best welding methods in production.

The first reason is the significantly low heat input and the corresponding minimum melting zone. This ensures the lowest possible shrinkage and distortion constant. If less metal is melted, the shrinkage and distortion are also very low. This allows precision machined components to be welded together with little or no secondary machining effort. Other advantages are the high efficiency of heat utilization and the low operating costs. The actual consumption of gases, energy and amount of cooling is significantly higher in most other welding processes. Laser welding is regarded as a process that comprises on of the most extensive range of thermally joinable materials, making it the most efficient form of fusion welding.

In summary, it can be concluded that the actual welding costs may only be considered to a limited extent. Therefore, only an assessment of the complete production chain can provide a definite conclusion about possible cost and energy savings potentials. The energy and cost saving potential often lies in the upstream and downstream processes.

It is evident that improved and swifter measures will be necessary to protect the climate in the future. Efficiency is a broad task, and anyone can do or consciously refrain from doing something at any time. Therefore, private business can also contribute to a more climate-friendly future through wise and intelligent decision making.

Energy efficiency in welding technology!

Reduce Energy Consumption in Your Welding Operations

Joining processes of metal consume significant amounts of energy and resources. The generation of energy efficiencies is a technologically and economically complex subject area. Not only electrical performance data should be evaluated, but a holistic view of the manufacturing process should be considered as well. Among other things, this includes work and weld seam preparation and the positioning of the parts being welded. In addition, the energy input, degree of melting, welding speed and cost efficiency should also be examined. Repairing welds, the correction of welding defects, the removal of spatter and straightening due to thermal distortion are also contributing factors. These efforts consume are time, material and energy. Depending on the process, a wide variety of auxiliary materials such as inert gases, welding consumables, etc. are required.

Fusion welding is defined as the melting and subsequent merging of the resulting molten mass. This process takes place without the application of force and with or without a filler metal. The energy efficiency of the entire process can vary greatly, even with identical welding results. Intelligent welding processes have a significant influence on the use of energy, materials and manpower. This is because each process directly influences the upstream and downstream production steps or at best eliminates them. A system for evaluating all joining processes with relevant comparison data does not exist, which means that energy estimations only provide an approximate result.

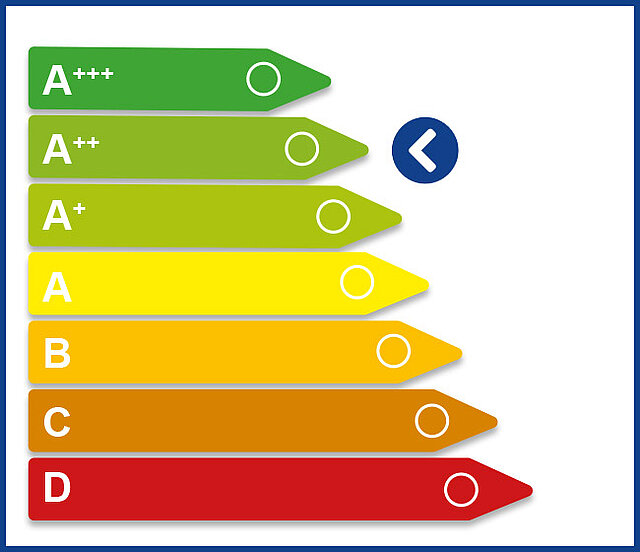

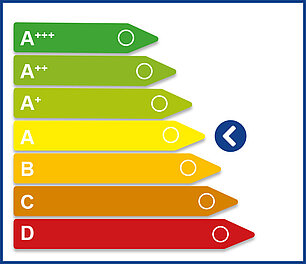

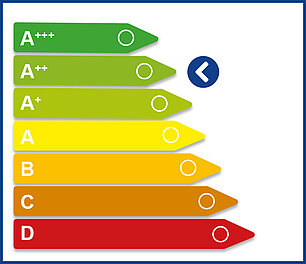

During the evaluation process, seven different energy classes were defined.

The estimates ranged from the unfavorable D to the top value A+++.

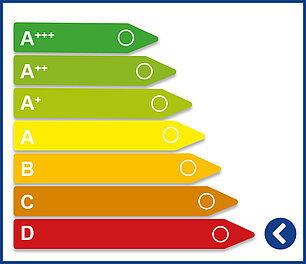

GAS FUSION WELDING

Energy efficiency Class: D

Gas fusion welding (also known as autogenous welding) is an old method still in use today. The metal is heated to the melting point with a torch flame. The required equipment consists of an acetylene and an oxygen cylinder with a mixing valve on the torch. The temperature of the flame is approx. 3200 °C. In most cases, a welding wire is used as filler material in this process. Due to a slow welding speed and considerable workpiece deformation caused by high heat effects, this process is becoming less and less desirable for cost and efficiency reasons.

MANUAL ARC WELDING

Energy efficiency Class: C

Manual arc welding (also known as electrode manual welding) is one of the oldest electrical welding processes for metallic materials and works by using the flow of an electrical current. The welding arc is several thousand degrees hot and acts as a heat source to melt the material at the joining zone. Depending on the process, there are melting and non-melting electrodes as well as free-burning and constricted arcs. The temperature of the arc is determined solely by the voltage and current. Therefore, arc welding processes can be controlled easily by regulating the voltage. However, in the ecological balance, manual electrode welding causes the greatest environmental damage due to the gases released. Welding devices for manual electric welding are relatively small and inexpensive.

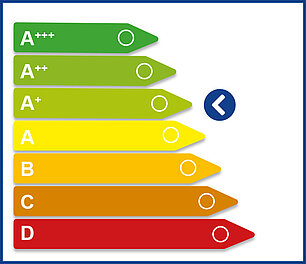

TUNGSTEN INERT GAS WELDING (TIG)

Energy efficiency Class: A+

In TIG welding, an electric arc burns between the workpiece and a tungsten electrode. It requires a non-melting tungsten electrode and a gas (usually helium or argon) that prevents oxidation. A filler material in the form of a welding wire is often added for joining. The tungsten electrodes are available in different diameters and lengths and must be sharpened according to the type of current. In direct current welding, the electrodes are sharpened like pencils, whereas alternating current welding requires a rounded shape of the electrodes. TIG welding is a method that can be used to process almost any material that can be welded by fusion. It is suitable for almost all welds in root and constrained positions. TIG welding is much slower compared to other methods but produces excellent weld seams and makes it easy to control the weld pool. Therefore, this method is preferred for smaller and shorter welding points. As a disadvantage, it should be mentioned that TIG welding causes a considerable distortion of the component. Furthermore, the initial investment is higher compared to TIG/TAG welding, but this is also reflected in the quality achieved. TIG welding is considered to be a "clean" welding process that produces little welding fumes, which is why it is often undervalued. The process involves health risks that should not be underestimated: welders are exposed to a high degree of nitrogen oxides and ozone.

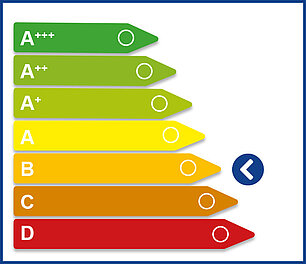

INERT GAS METAL ARC WELDING (TIG/TAG)

Energy efficiency Class: B

Inert gas metal arc welding (also known as inert gas welding) is an arc welding process which consists of TIG and TAG welding. With both methods, a melting welding wire is continuously fed at a variable speed. An additional gas is supplied to protect the materials from oxidation.

- TIG welding (metal welding with inert gases) usually uses argon or helium gas. The process is used for non-ferrous metals.

- TAG welding (metal welding with active gases) uses either a mixture of argon and nitrogen or just nitrogen. It is suitable for all ferrous metals.

Both methods allow for very long and regular welding seams and are suitable for more than just manual application. During robotic welding, spatter and clogged welding nozzles cause unstable processes and poor welding results, and the production process must be interrupted frequently in order to clean the nozzles from weld spatter. The energy efficiency here requires less spatter, a significantly higher welding speed and significantly improved gap bridging.

PLASMA WELDING

Energy efficiency Class: A

Plasma welding uses a high-temperature gas mixture of helium and argon or argon and hydrogen, which protects the melt from oxidation and stabilizes the arc. The arc burns between a non-melting electrode and the material. The plasma beam used as a heat source is generated by the high energy supply, which transforms the inert gas into an electrically conductive state. Similar to TIG welding, the arc is formed between a non-melting tungsten electrode and the base material during plasma welding. However, unlike TIG welding, the arc is constricted by the welding torch construction using a water-cooled copper nozzle, which results in a comparatively higher power density. Plasma welding is suitable for all electrically conductive materials. It is widely used and covers, for example, applications in micro welding technology and pipeline construction.

Joint welding with plasma can be broken down into three process variants:

- Microplasma welding for the thinnest sheet thicknesses starting at 0.01 mm

- Plasma welding for sheet thicknesses between 1–3 mm

- Plasma keyhole welding up to approx. 8 mm in one layer

Keyhole requires costly preparation and complex technology. Almost all metals and their alloys are weldable, with the possibility of joining different materials.

LASER WELDING

Energy efficiency Class: A++

This process is mainly used for welding components with limited welding depths. The laser beam is focused on the workpiece with the help of an optical system. Difficulties can arise when welding shiny materials, since copper is highly reflective of light, which makes it extremely difficult to melt the surface.

A large part of the laser power is absorbed by the shiny surface, which requires an increase in the energy used. This varies depending on the material and depends on the angle, temperature, polarization and wavelength. A significantly lower degree of absorption of copper compared to steel materials can be observed in the 1 μm wavelength range of a solid state or fiber laser.

ENERGY EFFICIENCY IN WELDING TECHNOLOGY

One thing, in particular, is clear: based on the analytical criteria provided, laser welding performs significantly better than all other common fusion welding processes.

The global discussions on climate change and the environment are increasingly calling the use of resources and energy consumption in production into question. Sustainability, life cycle assessment and energy efficiency are terms used in these discussions that are particularly critical of production and manufacturing processes.