WOBBLE LASER WELDING

The Welding Revolution

What is wobble laser welding?

Wobble laser head - Trepanning laser head - stirring laser head

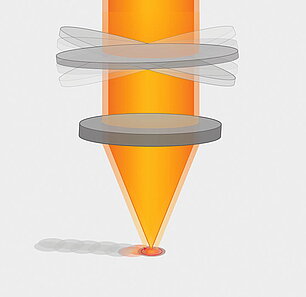

Standard laser welding heads are designed to focus a collimated laser beam to ONE required spot size, keeping the beam path static. This standard configuration limits each setup to ONE specific application.

Our Wobble heads, on the other hand, incorporate scanning mirror technology inside our weld head. By moving the beam with internal mirrors or rotating lenses, the focal spot is no longer static and can be dynamically adjusted by changing the shape, amplitude and frequency.

Wobble welding

=

Laser stir welding (LSW)

=

Trepanning laser welding

Laser Wobble Welding or Laser Stir Welding

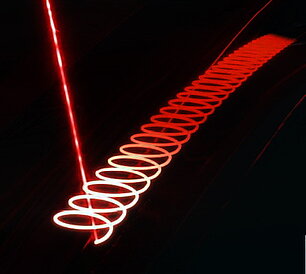

Laser stir welding or Wobble Welding is a process in which a continuous beam laser is oscillated or wobbled at a relatively high frequency, which causes a stirring action within the molten weld pool – hence the term “stir welding or Wobble Welding.” The result is a manipulation of the weld pool/vapor cavity, which changes some key characteristics of the weld.

Benefits:

- Laser Stir Welding results in largely defect free joints, with no hot cracking, porosity or solidification cracks.

- More precise control of the weld pool for increased keyhole stability.

- Improved control of the profile and geometry of the weld – as an example, joints can be designed with more width at the root of the weld, which can be very useful for Lap/Thru-/Blind welds.

- Weld profiles can be manipulated into asymmetry, such as increasing the penetration on one side of the weld joint.

- Patterns can be programmed to compensate for large gaps in weld joints and other potentially problematic weld geometry problems.

- Higher feed rates can be achieved than with pulsed laser techniques.

- No filler materials is required.